The paper machine is a complete set of equipment to make the pulp form the web, including headbox, net part, press part, dryer, calender, Winder, transmission part and other main machines, as well as steam, water, vacuum, lubrication, heat recovery and other auxiliary systems. The web forming the wet web is the core of the paper machine, so the paper machine can be divided into long web paper machine, pinch web paper machine and round web paper machine according to the web structure.

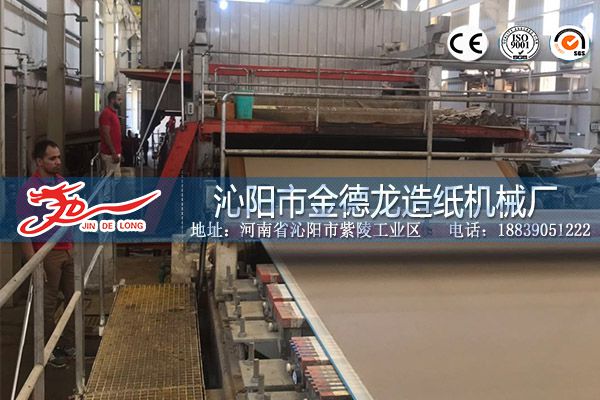

Headbox is a kind of equipment which can send the pulp of appropriate concentration to the net evenly and stably through the distributor, rectifying device, weir pool, weir plate nozzle and other parts, also known as the net front box. After the pulp is sprayed from headbox to the copper net, the wet paper is formed on the net and dehydrated. Then it is pressed, that is, the moisture of the wet paper is extruded from the net by mechanical method to improve the dryness of the paper At the same time, it can improve the surface properties of the paper, eliminate the net mark and increase the smoothness, tightness and strength; then it can enter the drying section to further dehydrate the wet paper after pressing, so as to shrink the paper, make the fiber bond tightly and increase the strength.

After calendered by calender, the smoothness, glossiness and compactness of the paper sheet can be improved, the thickness of the whole sheet can be consistent, and the air permeability can be reduced; at least, the paper sheet can be rolled into a paper roll by the winder, which completes the main process of papermaking. In order to meet the different needs in the future, there are also super calender, rewinder, paper cutter and so on behind the winder in the paper workshop.

Paper industry will consume a lot of raw materials, water, electricity and chemicals, and produce a lot of wastewater and waste residue. Therefore, the future of paper machinery will use a wide range of paper-making raw materials, reduce the consumption of materials and energy in the paper-making process, and reduce environmental pollution.